3D printing: a real revolution?

Still a long way to go to change the production system

Still a long way to go to change the production system

It was 2011. The Economist shouted “Revolution!” and put on its cover a plastic violin, headlining in large letters: “Print me a Stradivarius”.

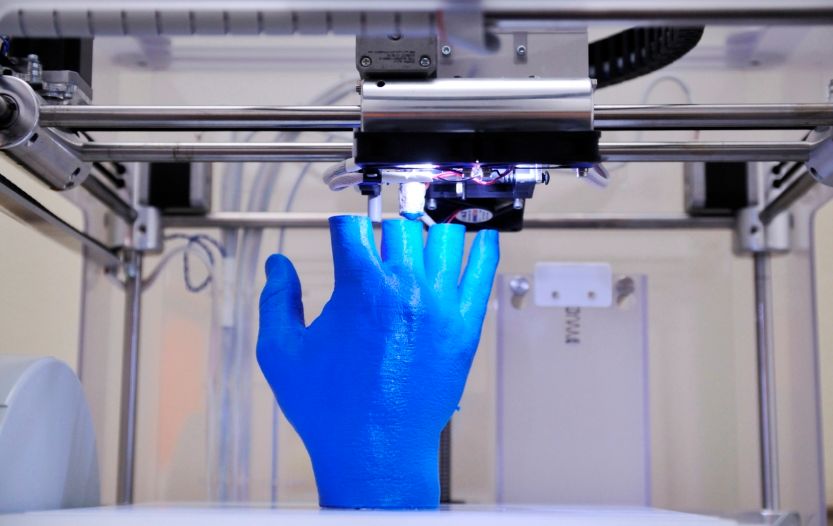

In five years, 3D printing technology has made great progress, expanding the range of materials – including glass – and lowering the cost of machinery, now also available with a few hundred dollars.

A few days ago, it was reported the news the presentation of the M1, the first 3D printer in the world using the CLIP-Continuous Liquid Interface technology, announced a year ago by 3D Carbon. It’s a technology that has great advantages, especially in terms of speed and the absence of "layers" in the press, with all the consequences, such as the resistance of the printed object.

There are, apparently, a few obstacles to the effective realization of the slogan “If you can think, you can print”, launched by technicians and enthusiasts who imagine in their mind a technological costs reduction future and an irresistible triumph of open-sources.

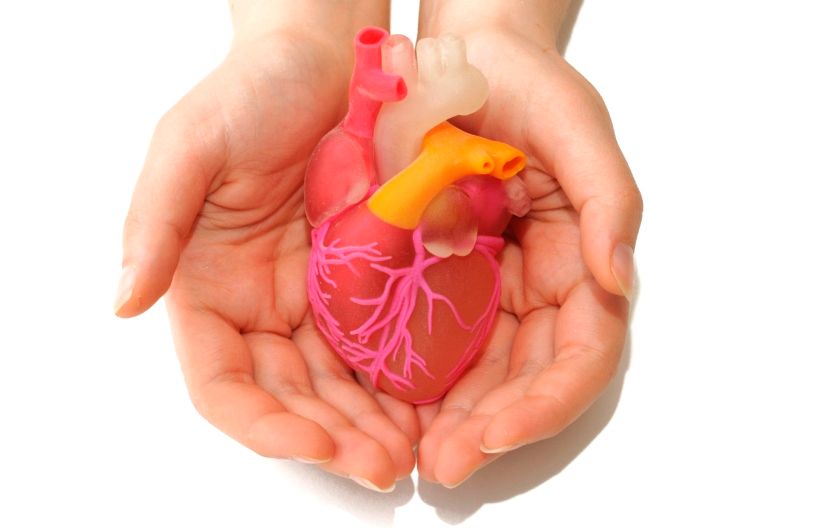

Other experts, however, are more cautious. According to Gartner, a world's leading information technology research and advisory company, the adoption of 3D printing technology is going to have a real boom in medical and professional field, but to become mainstream in the retail world, it will need some time; also considering that the enterprise market is quite different from the consumer market.

Nowadays, 3D printing involves a complex ecosystem of software, hardware and materials “whose use is not as simple to use as 'hitting print' on a paper printer,” said Pete Basiliere, research vice president at Gartner. And the price is still too high for mainstream market.

Certainly, 3D printing is constantly evolving and in great growth for demand, both as interest that as a demand. And there are some very spectacular uses, such as the painting called “New Rembrandt”, that has been recently developed in Amsterdam. Not a creation by the genius of the 17th century, but an artwork by a 3D printer, using a software and a facial recognition algorithm that thoroughly explored all 346 Rembrandt’s paintings.

In the field of art history, there are also those, like the Iranian artist and activist Morehshin Allahyari, who wants to use 3D printing to repair the colossal damage caused to artworks and artifacts by Daesh in recent years. Paolo Matthiae, archaeologist and emeritus professor of La Sapienza University, has the same view. According to him, the 3D printing technique may be useful to restore what has been destroyed by the fighting in Syria¸ even if it means the forgery of historic artworks.

Moreover, lunar surface portions, braces that can replace the plaster cast in case of fracture, food for astronauts… 3D printing seems to lend itself more than ever to the experiments.

Of course, as with any new technology, the enthusiasm goes hand in hand with criticism. Among the most popular, the large amount of dust, debris and chemicals generated from domestic production and the cost of raw materials, that goes through the roof; this without mentioning the economic and social consequences that a decentralized production could bring, as well as the intellectual property issues related to the use of shared files.

Fears aside, it’s clear that many countries around the world have started for a long time the race to grab a portion of leadership in this up and coming industry – in particular the US’ giant Stratasys -, making more credible the hypothesis of a new industrial revolution.

Considering the ongoing situation, we can’t evaluate the impact of this technology on our lives. The most likely scenarios include “selfies of the future” of 3D figurines, and 3D printing kiosks in shopping malls, maybe just where once stood the now obsolete photo developing shops.